applicazioni:

4 Heads Automatic Liquid Bottle Filling Machine is suitable to the material: coating agent, suspension agent, edible oil, lubricating oil and water agent etc.

Il principio e la caratteristica:

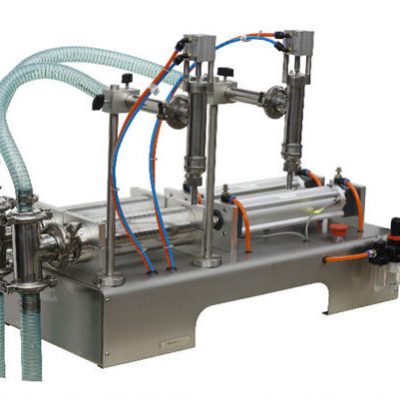

The machine is a ram filler, it using the PLC programmable control, equipping with tonching screen person-machine interface system, realizing automatic filling, automatic capping. it is suit for the different bottles and caps, only make some adjustment .

Caratteristica:

1. SS316L piston pump fills high precision suitable for oral liquid and light liquid with viscosity.

2. This machine is compact design, streamline bottle conveying, more stable.

3. No bottle no fill function.

4. Auto frequency conversion adjusting speed.

5. Auto display and count.

6. Rolling sealer uses single flexible knife with 12 rolling heads, one machine can auto entry, filling, adding cap, and sealing smoothly.

7. One machine can auto entry, filling adding capper, and sealing.

8. The whole machine is designed according to the requirements of GMP.

Principali caratteristiche tecniche

| Numero di teste di riempimento | 4 teste |

| Numero di teste di torsione | Testa singola |

| La gamma di riempimento | 20 ~ 1000ml |

| La gamma di perfetti | 20-100 ml \ 50-250 ml \ 100-500 ml \ 200 ml-1000 ml |

| La scelta della copertina | Copertura antieffrazione, copertura a vite, copertura in alluminio ROPP |

| Capacità produttiva | 2400 ~ 3000 (bottiglie / ora) |

| Misura la precisione | ≤ ± 1 |

| Il tasso di ammissibilità | ≥99 |

| Energia | 220V 50 / 60Hz |

| Potere totale | ≤1.2kw |

| Pressione dell'aria | 0.4 ~ 0.6MPa |

| Peso | 800kg |

| Dimensioni esterne (mm) | 2000 × 1200 × 1600 |

Info Veloci

Tipo: Riempitrice

Condizioni: Nuovo

Applicazione: bevanda, chimica, medica

Tipo di imballo: Bottiglie

Grado automatico: automatico

Tipo guidato: elettrico

Voltaggio: 220 V / 110 V 50 / 60Hz

Potenza: ≤1,2 kW

Luogo di origine: Shanghai, Cina (continente)

Nome del marchio: VKPAK

Dimensioni (L * W * H): 2000 * 1200 * 1600mm

Peso: 800kg

Certificazione: GMP

Servizio post-vendita fornito: ingegneri disponibili per la manutenzione di macchinari all'estero

Nome prodotto: Riempitrice di bottiglie liquide

La gamma di riempimento: 20 ~ 1000 ml

La gamma di perfetti: 20-100 ml \ 50-250 ml \ 100-500 ml \ 200 ml-1000 ml

Capacità produttiva: 2400 ~ 3000 (bottiglie / ora)

Precisione di misura: ≤ ± 1

Il tasso di ammissibili: ≥99

The choice of cover: Burglarproof cover, screw cover

A 4 heads automatic liquid bottle filling machine is a piece of equipment designed to fill bottles with liquids such as water, juice, oil, and other fluids. This machine works by accurately measuring and dispensing the required amount of liquid into the bottle through four filling heads that work simultaneously. The machine is fully automated, which makes the process faster, efficient, and less labor-intensive.

The 4 heads automatic liquid bottle filling machine is designed to handle a range of bottle sizes and shapes, making it versatile and ideal for use in a variety of industries. The machine can also fill different types of liquids, which makes it a suitable option for use in industries such as food and beverage, pharmaceuticals, and cosmetics.

The machine is easy to operate and has a user-friendly interface that allows for easy setup and programming of the filling parameters. The parameters can be customized to suit the specific needs of the product being filled, such as filling volumes and speeds.

The filling process is accurate and consistent, which helps to maintain the quality of the product being filled. The machine can also be integrated with a capping or labeling machine, which further streamlines the packaging process and increases efficiency.

In conclusion, a 4 heads automatic liquid bottle filling machine is an essential piece of equipment for any business that produces and bottles liquid products. It provides a fast, efficient, and accurate way of filling bottles with liquid products, which helps to increase productivity and reduce costs. The machine is customizable and can handle a range of bottle sizes and types, making it versatile and suitable for use in various industries.